Distilled Spirits Solutions

From blending to end-of-line, ProMach is a leading provider of superior processing and packaging solutions for the distilled spirits industry. Trusted by some of the most well-recognized names in the industry, ProMach technologies are used around the globe to not only meet but exceed packaging performance. 15+ product brands provide expert solutions to our client base of 385 global customer locations producing the best-tasting spirits in the world.

CUSTOMER HIGHLIGHT

Tradition at Maker's Mark Includes ProMach Product Brands

To preserve the lasting legacy of the Samuel's family original bourbon recipe, Maker's Mark relies on long standing traditions for their distilleries. To ensure their bottling line runs at peak performance, Maker's Mark also relies on Fogg, Zalkin, and P.E. Labellers to fill, cap, and label their highly regarded product.

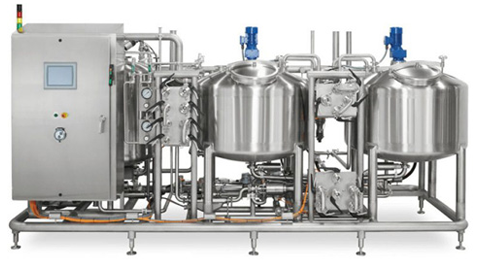

Processing Technology

ProMach is your dedicated processing partner for distilleries and those producing RTD alcoholic beverages. From large-scale producers to new small-batch micro-distillers, product brands TechniBlend and Statco-DSI together offer a powerful suite of processing solutions tailored to fit the unique needs of your operation. From precise batching and seamless blending to advanced ESL/Aseptic capabilities and efficient CIP systems, our offerings encompass the entire spectrum of your production requirements.

NOTEWORTHY APPLICATIONS

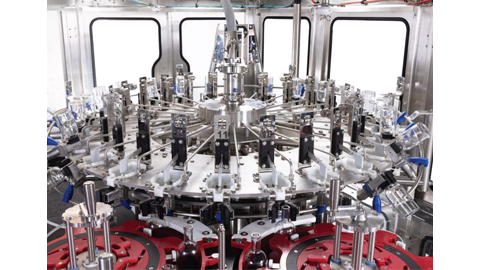

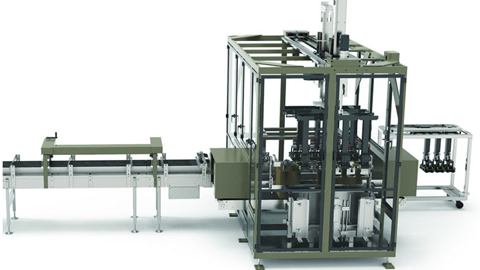

Tailored Filling Solutions

Tailored to meet the exacting demands of the distilled spirits industry, Fogg is the recognized expert in the art of precision filling. Whether your filling requirements are for 50ml bottles or 1.75 liter bottles, our solutions encompass a wide range of capabilities spanning from 30 bpm to an impressive 1000 bpm. As the spirits industry evolves with more unique products and blends to suit customers’ needs, Fogg tailors their fillers to accommodate.

With these new spirits products, there has come a need for greater sanitation. From unscrambling to rinsing, filling, and beyond, our filling brands understand the preciseness required in the spirits industry. Seamless, efficient, and high-speed filling starts with ProMach.

NOTEWORTHY APPLICATIONS

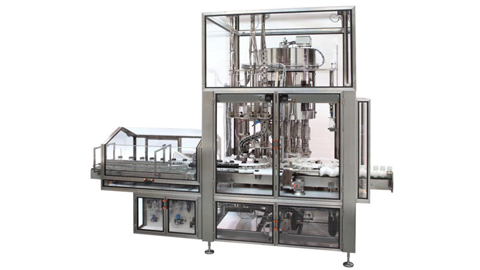

Capping

Precise capping is imperative for the success of distilled spirits packaging lines. Every closure type requires proper handling, with an emphasis on those with unique shapes, high-gloss finishes, intricate embossing, or crafted from delicate glass. Zalkin and PackWest lead the spirits industry addressing the evolving demands of their customers with high-performance capping.

They know how important it is for the delicate treatment of such closures to safeguard against even the slightest visual imperfections to keep your line moving without interruption. Capping capabilities include cap feeding, closure orientation, cap handling, inline spindle cappers, and delicate bottle management, from 40 - 900 bpm.

NOTEWORTHY APPLICATIONS

Product Labeling

From decorative labeling, shrink sleeve and tamper evident banding, coding, and beyond, ProMach labeling and coding capabilities for the distilled spirits industry is innovation at its finest. P.E. Labellers, synonymous with primary label applications for the spirits industry with custom solutions for a wide range of customers production needs. Meanwhile, Axon boasts mastery in shrink sleeving, accompanied by an expertise in tamper-evident banding, which particularly benefits high-value items.

In the realm of labeling and coding, our experts—ID Technology, WLS, and Code Tech—unite their strengths to address primary and secondary application needs. From intricate labeling solutions to precise coding, ProMach is your trusted partner in achieving faultless presentation and robust tracking for your products.

NOTEWORTHY APPLICATIONS

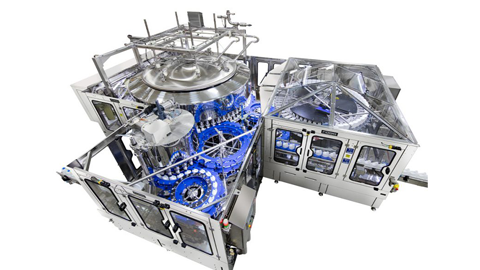

Case Packing, Cartoning, and Multipacks

Whether your product is in a 50ml bottle or in a 750ml bottle, ProMach has tailored end of line solutions for your packaging operation. ProMach provides case packing, cartoning, case erecting, shrink wrapping, bundling, pallet wrapping, and beyond. Products are safe during transit are production goals are exceeded. Whether it's about ensuring the safety of your product or elevating your production efficiency, ProMach's secondary packaging and end-of-line brands guide you toward packaging excellence.

NOTEWORTHY APPLICATIONS

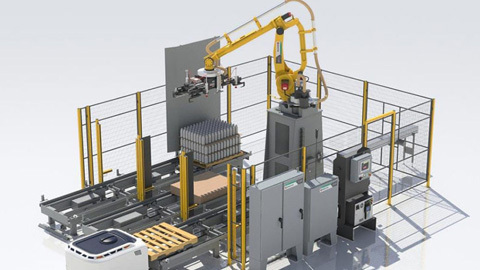

PALLETIZING AND STRETCH WRAPPING

Palletizing and stretch wrapping play a pivotal role in distilled spirits packaging lines, representing essential components for efficiency and product integrity. As the demand for ready-to-drink beverages surges, precision and reliability become paramount. Palletizing systems from Brenton and Quest efficiently arrange and organize finished products on pallets, adhering to the exact requirements of the ready-to-drink industry. Stretch wrapping from Orion ensures the stability and security of these palletized loads, safeguarding against damage during transit and storage. This combination of robotic palletizing and stretch wrapping not only optimizes production line performance but also enhances the overall product quality and integrity. It's a synergy that underscores the critical importance of these processes in the seamless packaging of ready-to-drink beverages.

NOTEWORTHY APPLICATIONS

Systems and Integration

From process through to the packaging line, ProMach provides numerous points of support for your production. For a single touchpoint Single source supply, project management & performance guarantee from process through packaging line.

NOTEWORTHY APPLICATIONS

CUSTOMER HIGHLIGHT

High West Distillery Relies on Fogg For Expert Filling and Capping Systems

As High West's business continues to expand, the team continues to rely on Fogg to meet the challenges of a demanding packaging line. Fogg not only provides distilled spirits filling expertise, but provides custom solutions for High West with tailored rinsing systems, CIP, product discharge, reclaim systems, and much more to align perfectly with High West's specific requirements.

WATCH NOW