Pet Care Solutions

At ProMach, we understand the unique challenges of producing wet food, kibble, treats, and more for our furry pals. We are committed to ensuring that your products maintain their utmost freshness, taste, and shelf stability – crucial factors in satisfying discerning pet owners. We recognize that maintaining a loyal customer base is paramount in the competitive pet food market. This is why our solutions go beyond production efficiency, from retorting to flexibles and labeling for shelf differentiation through your unique branding styles. With an awareness of the pet food industry's dynamic landscape, we stand ready to elevate your products and exceed your production goals.

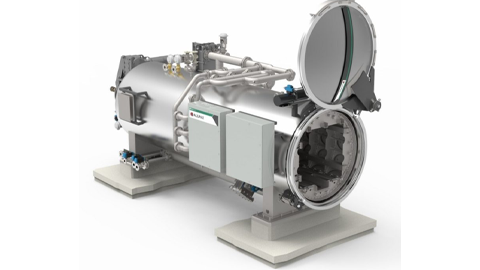

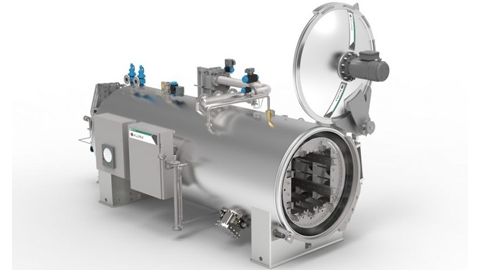

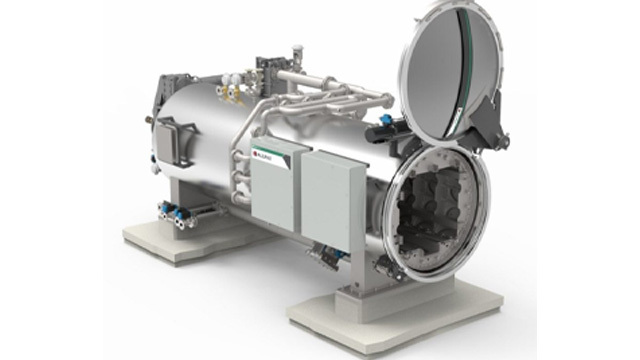

Batch Retorting, Cooking, and Sterilizing

Allpax helps wet pet food manufacturers with batch retorting solutions, cooking, and sterilizing so your product is of quality taste in every package. Allpax retorts feature FDA and USDA-compliant control software and their process logging software has become adopted throughout the industry. Their retorts are known for versatility, high throughput, and reliability so that the total cost of ownership is low and production goals stay high.

NOTEWORTHY APPLICATIONS

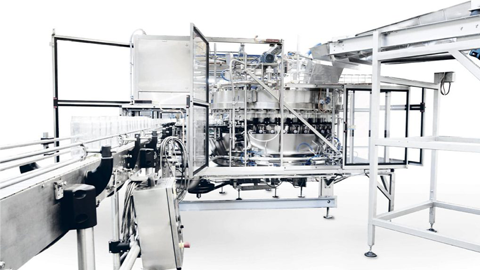

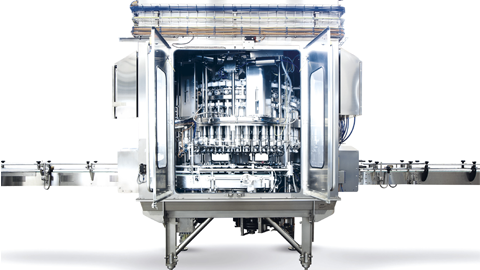

Filling and Seaming

The addition of Zacmi to the ProMach product brand portfolio significantly enhances ProMach's capability to provide a range of solutions for can filling and seaming lines for the pet food industry. Zacmi is one of the food industry's most respected suppliers of high-quality filling, closing and sterilization equipment for pet food products, as well as seamers for metal cans.

NOTEWORTHY APPLICATIONS

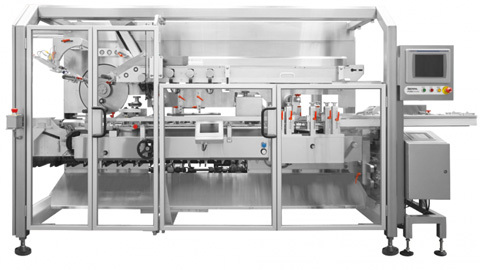

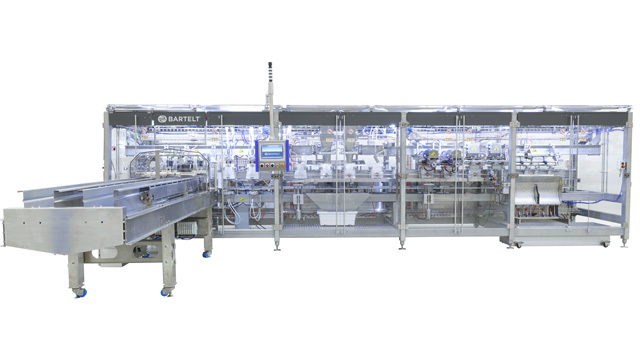

Flexibles

For dry kibble and treats, packaging your product into a variety of bag styles and sizes is one of the most important aspects of your packaging line. Matrix and Bartelt are market leaders in vertical and horizontal form fill and seal for a wide variety of bag and pouch styles, including large pillow bags, flat bottom bags with pre-applied zipper, gusseted, pre-made pouches, and beyond.

NOTEWORTHY APPLICATIONS

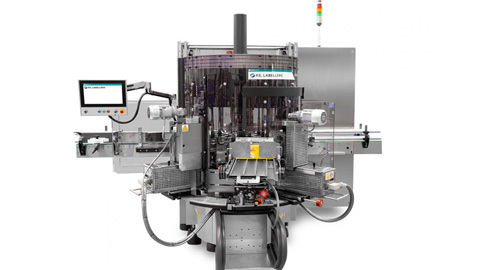

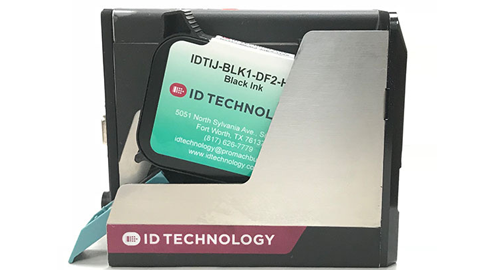

LABELING AND CODING

Effective labeling and precise date coding play a pivotal role in presenting your product, ensuring visual appeal, information transmission, and uninterrupted movement down the packaging line and out to customers. ProMach labeling and coding brands offer expert solutions that allow pet food manufacturers to deliver top-tier packaging while optimizing the efficiency of their packaging lines. Whether it’s directly on the flexible package, secondary packaging and pallet labeling, a labeling and coding brand has your solution.

NOTEWORTHY APPLICATIONS

CASEPACKING, SHRINK WRAPPING, CARTONING, AND PALLETIZING

For the last step before your products get shipped to retailers, ensuring your end-of-line operation can keep up with the rest of the line is essential for production goals. Shrink bundling your product into multipacks, case erecting, robotic case packing, and stretch wrapping and pallet wrapping are all imperative to function at peak efficiency.

NOTEWORTHY APPLICATIONS

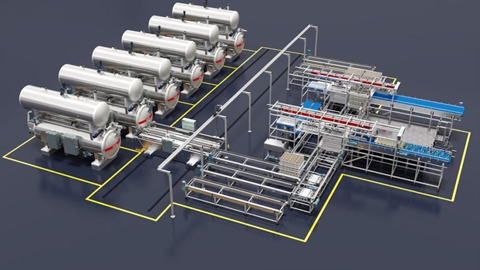

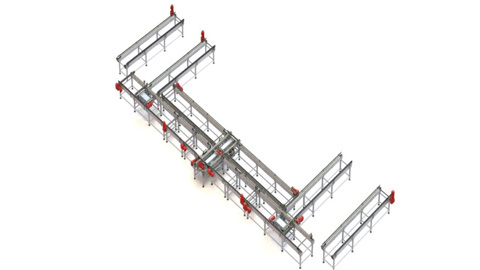

Systems and Integration

Specializing in integrated, OEE availability-optimized turnkey packaging lines, Zarpac offers unmatched expertise in packaging line engineering services. Our capabilities extend to encompass custom packaging equipment design and build, ensuring that your production line is tailored to your specific requirements. With the addition of Sentry, a leading supplier of high-quality conveyors, packaging equipment, container handling solutions, and related services, ProMach can now provide a complete solution for conveyor and container handling machines.