Ready-To-Drink Solutions

To preserve the taste, freshness, and quality of your ready-to-drink single serve beverage such as energy drinks, coffee, craft cocktails, juice, water, craft beer, and more, ensuring precise and accurate packaging is paramount. From processing, filling, and seaming, to labeling and coding to multi-packing, ProMach’s best in class packaging solutions for ready-to-drink beverage lines are your partner in the success of product and packaging goals.

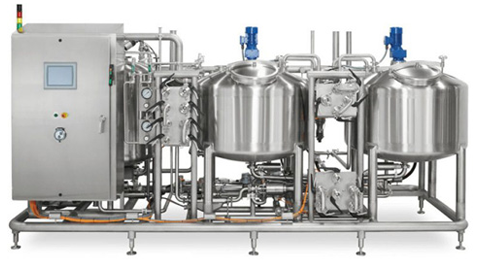

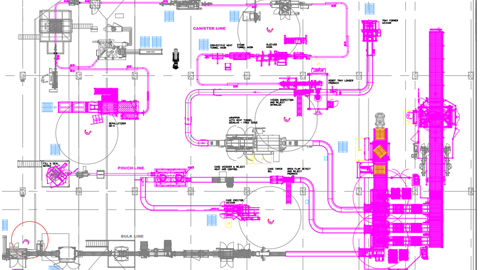

PROCESSING & BLENDING

ProMach's process group has two of the industry's largest and most respected processing brands: Statco DSI and Techniblend. ProMach's goal is to meet our customers' needs from the formulation and blending of products, all the way through the palletization of finished goods. Our processing groups serve a number of sectors of the ready-to-drink industry, including soft drinks, coffee, large brewery, energy drinks, craft brewers, distilled spirits crafted cocktails, and alternative beverages such as kombucha, to name a few.

NOTEWORTHY APPLICATIONS

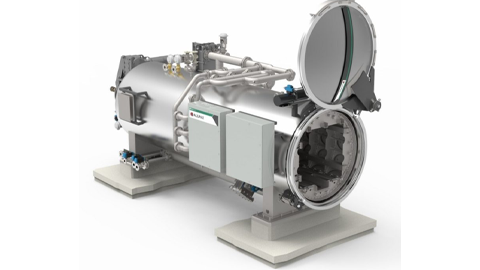

STERILIZATION & RETORT

With significant growth in the production of commercially sterilized ready-to-drink (RTD) beverages in the US, Allpax plays a key role in this expansion. Allpax possesses the largest installed base of rotary water immersion retorts, which serve the RTD beverage processing industry. Batch retorts offer smaller processors an entry point into this growing market, thanks to lower barriers to entry in terms of capital and regulations compared to aseptic processing.

NOTEWORTHY APPLICATIONS

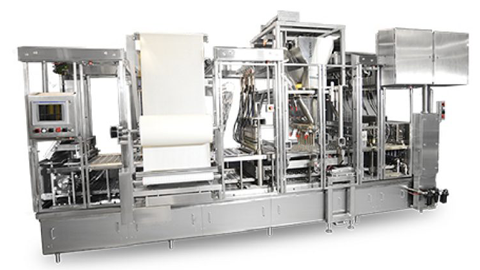

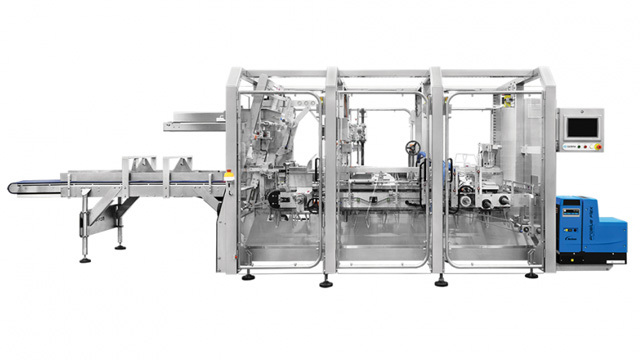

FILLING

TechniBlend, Fogg, and Modern filling systems give today's rapidly growing beverage producer industry the platform and technology to meet today's production requirements. We address the ready to drink market filling needs for cups, bottles, cans, and more, and provides filling solutions for single serve cups for juice, water, and more. The entire line of filling systems is designed around maintaining the highest levels of product quality while delivering best-in-class levels of production efficiency, throughput, reliability, and simplicity.

NOTEWORTHY APPLICATIONS

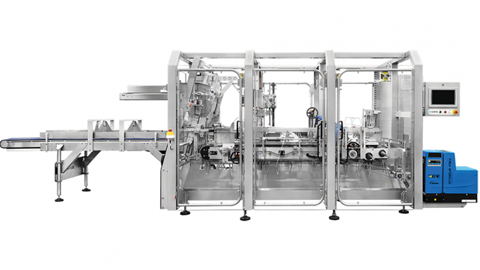

SLEEVING & LABELING

Today's beverage manufacturing spans a wide variety of sizes and shapes for water, wine, beer, spirits, soft drinks, and juices. CL&D provides flexographic and digital printing that exceeds printing material quality. P.E. Labellers is an industry leader known worldwide for advanced labeling capabilities and cutting-edge labeling technology. ID Technology's range of labeling, marking, and coding solutions enables you to achieve safe and reliable identification in a wide range of beverage industry environments.

NOTEWORTHY APPLICATIONS

CARTONING, CASE PACKING, SHRINK BUNDLING, AND MULTIPACKING

When your product is ready to be multi-packed, rely on ProMach for reliable solutions for the safe transfer and stand-out packaging for your product. ProMach product brands are leaders in the design of innovative, robust packaging equipment including, can handles, can handle applicators, and cartoners.

NOTEWORTHY APPLICATIONS

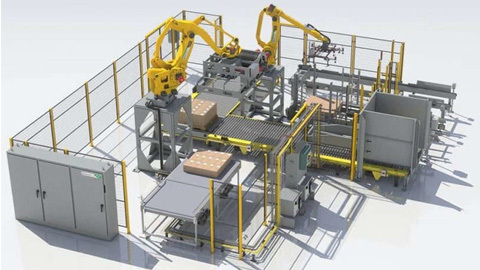

PALLETIZING

In the fast-paced world of beverage manufacturing, precision and speed are critical components to your packaging line success. Robotic palletizing is a versatile and reliable solution, that efficiently stack products, ensuring precise configurations tailored to ready-to-drink industry needs. Brenton and Quest excel in robotic palletizing and are known across the industry for advanced robotic technology. Brenton and Quest's solutions adapt to different bottle sizes and packaging, reducing downtime, minimizing damage, and boosting efficiency. Robotic palletizing is vital for seamless ready-to-drink production, optimizing processes and performance.

NOTEWORTHY APPLICATIONS

Systems and Integration

Zarpac specializes in creating turnkey packaging lines that are finely tuned for maximum OEE (Overall Equipment Effectiveness) availability. Coupled with product handling by Statera, our team possesses unparalleled expertise in the realm of packaging line engineering services. Our capabilities go beyond standard offerings, encompassing the design and construction of custom packaging equipment, tailored to meet your unique production needs. Partnering with Zarpac and Statera means tapping into a wealth of experience and innovation, ensuring a seamless integration of your dressings and sauces into the production line. This synergy sets new benchmarks in terms of efficiency, quality, and productivity, elevating your operations to unprecedented levels.