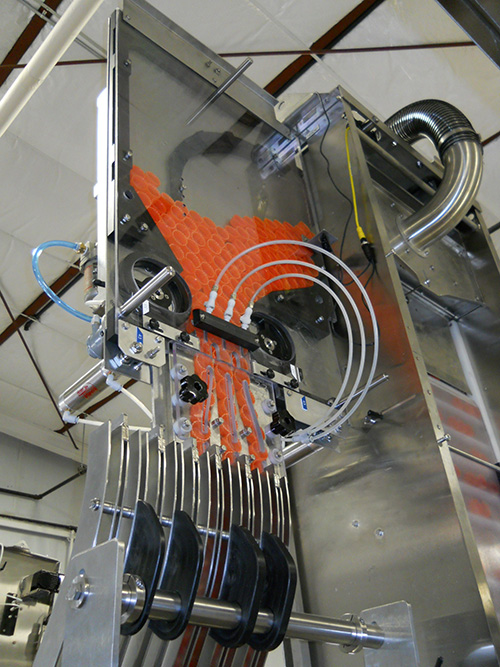

ATHENS, Georgia — Fowler Products, powered by ProMach, has developed what the company considers to be the industry’s first waterfall sorter with multiple lane discharge capabilities. This new solution is applicable to both bottlers and to cap manufacturers that print and/or insert liners.

ATHENS, Georgia — Fowler Products, powered by ProMach, has developed what the company considers to be the industry’s first waterfall sorter with multiple lane discharge capabilities. This new solution is applicable to both bottlers and to cap manufacturers that print and/or insert liners.

The new waterfall sorter with multilane discharge system delivers the following benefits:

- Lower cost than purchasing multiple sortation units

- High dependability in terms of orientation

- Fast changeove r

- Small footprint

Via conveyors, the sorter can be located remotely from capping and printing operations, which helps to keep those areas cleaner by eliminating shipping case dust and other small debris associated with transporting and handling shipping cases. Remote location decreases forklift traffic near capping, printing, or insertion stations to improve safety. Sortation near cap storage can also reduce time and labor spent moving caps.

The first of these new units was delivered to a cap manufacturer that was printing on 33, 38, and 43 mm caps with a three-head printing unit. The manufacturer had been using a rotary sorter to orient caps into separate lanes. There were two problems with this solution: The system did not dependably orient caps and changeover between cap sizes consumed too much time and labor.

Fowler based the solution on its waterfall sorter technology, which is recognized for dependability in orienting caps, and in concert developed a three lane, rather than the standard one lane, discharge system for oriented caps. No changeover is needed when going from 38 to 43 mm caps or vice versa. Changeover to 33 mm caps takes less than a minute thanks to a simple slide mechanism, which slides in three 33 mm discharge chutes. The new sorter was installed and running at full speed and efficiency in one day.

“Fowler works closely with its customers on developing innovations such as the waterfall sorter with a multilane discharge system,” said Andy Monroe, sales manager, Fowler Products. “We appreciate the opportunity to help manufacturers solve their capping productivity issues.”

For more information on the new multilane waterfall sorter and other Fowler Products solutions and services, including capping, cap handling, bottle cleaning, multi-unit system integration, and pulsed-light sanitation, call 1-877-549-3301 and visit www.FowlerProducts.com. Stop by the Fowler Products Booth C-2420 at Pack Expo 2013 to see some of the company’s most recent machines.

About ProMach

ProMach is a family of best-in-class packaging and processing solution brands serving manufacturers of all sizes and geographies in the food, beverage, pharmaceutical, personal care, and household and industrial goods industries. ProMach brands operate across the entire production line: processing, filling, bottling and capping, decorative labeling, flexibles and trays, pharma, handling and sterilizing, labeling and coding, and robotics and end of line. ProMach also provides systems and integration including turnkey solutions, design/build, engineering services, and productivity software to optimize production line design and deliver maximum uptime.

ProMach designs, manufactures, integrates, and supports the most sophisticated and advanced packaging and processing solutions in the global marketplace. Its diverse customer base, from Fortune 500 companies to smaller, privately-held businesses worldwide, depends on reliable, flexible, technologically advanced equipment and integrated solutions. ProMach is headquartered near Cincinnati, Ohio, with manufacturing facilities and offices throughout North America, Europe, South America, and Asia. For more information about ProMach, visit www.ProMachBuilt.com and for more information on ProMach Careers, visit www.ProMachCareers.com.